Making barley malt. Preparing malt for moonshine at home.

From high-quality barley grain, aged for at least 60 days, which must have a germination rate of at least 90%. Freshly harvested and unseasoned varieties have insufficient ability to germinate.

Washing, disinfection, soaking

We heat the water to 40-50° C and wash the barley, simultaneously removing all debris and unsunk grains. Next, fill the container just above the layer of grain with water cooled to 10-15°C, stir well, once again remove the floating grains and debris and leave for 60-90 minutes. After this, pour out the dirty water and add fresh water. We prepare a solution for disinfection from potassium permanganate or iodine. You need approximately 10 liters of potassium permanganate on the tip of a knife or 40 drops of iodine. Mix and leave to disinfect for 2-3 hours. Disinfection can also be carried out using 1-5% lime.

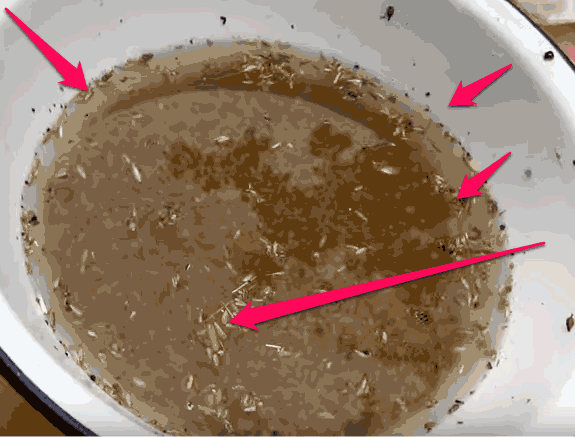

Drain the used solution and soak in water cooled to 9-17°C, slightly covering the grain. Leave in a dark and cool room for 6 hours. After 6 hours, drain. Next, mix and leave without water for 6 hours. We repeat this procedure for two days.

Germination

The ideal temperature for germination is 12-16° C. It allows you to stimulate the degree of protein breakdown in barley. The height of the barley layer varies from 1 to 6 cm and depends on the temperature in the malthouse. If the room is cold, you can increase the thickness of the layer, but you need to make sure that the grain does not heat up too much. By adjusting the thickness of the poured layer, you should achieve a stable temperature and uniform germination.

Signs of ideal growth:

— the length of the roots for light malt should be from 3/4 to 1.5 times the length of the grain;

- for dark malt 1.5 - 2 times the length of the grain;

— the grain loses its mealy taste, becomes sweetish, crunches when bitten, and has the smell of a fresh cucumber. The formation of dried roots indicates loss of moisture due to disturbances in the malting process;

— the grains are easily crushed on your fingers and leave a powdery white mark. The sticky and elastic consistency of the endosperm indicates its lack of dissolution.

The growing time for light malt is up to 7 - 8 days, for dark malt - up to 9 days. The use of activators makes it possible to germinate in 5 - 6 days

Drying

You can dry and air freshly sprouted malt on a sunny day right outside, spreading it in a thin layer on the dryer. Next, you need to somehow, for example in the oven, increase the temperature to 40° C and leave for an additional 24 hours until completely dry.

The resulting malt can be used for the production of all types of strong drinks except. If you plan to make light malt for brewing homemade beer, it is advisable to carry out additional drying for 4 hours at a temperature of 80 ° C. To prepare dark malt, drying at 105 ° C for 4 hours is required.

Removing sprouts

Now our task is to remove the sprouts from the grains. To do this, pour the malt into any bag, tie it, and start rolling it. It is also possible to use a mixer and a bucket.

We remove fallen sprouts by winnowing the malt in the wind or using a fan.

aging

Pour the malt into bags and leave for a month. After this it is ready for use.

So, from this article you learned how to make your own malt.

All those who are not ready for such a feat can simply buy.

The use of malt has been known since ancient times, when winemaking and moonshine brewing just began. Currently, this product does not lose its popularity and is actively used as a raw material for starters, various drinks, in cooking, for the production of beer and moonshine. If we consider malt as a separate product, then it is the seeds of various cereal crops sprouted using a special technology, which lies in a certain classification, for example, red (fermented) is often rye, and white (non-fermented) is barley. In addition, there are types that differ in the scheme of preparation and cultivation of cereals, in particular, stewed, burnt, caramel and so on. Each option is selected relative to the main application, since during the preparation of malt the reactions occurring inside the plant can change, which is very important. It was precisely because of chemical changes during the period of sprouting that malt began to be actively used in the manufacture of sourdoughs and alcoholic beverages in general. Naturally starch is processed into sugar, which occurs, among other things, thanks to diastase formed during seed germination. The compound belongs to enzymatic substances and makes it possible to obtain starch-based sugar that has the ability to ferment, which is valuable for making mash.

Almost any cereal can be used as seeds, including rice, but wheat, rye, and barley are considered especially popular for the production of alcohol. If you adhere to technology, have high-quality equipment and do not neglect the basic rules, including the choice of raw materials, then moonshine from malt will not only have a good yield, but also taste good.

Sprouted cereals can be made at home, but it is important not to violate the technology regarding temperature and time conditions. It is better to start preparing malt with a minimum amount of seeds, since at first glance the simple process of processing cereals has certain features. For those who do not want to waste time on experiments, but want to get rye, wheat or any other similar alcoholic drink, you can purchase a ready-made version. Typically, such products can be found in stores specializing in everything necessary for moonshine brewing. It has already been initially prepared, taking into account all the features of germination, drying and aged in such a way that the seeds have not used up all their nutrients and are useful for fermentation.

How to make malt at home

You can grow and prepare malt with your own hands, but this will require strict adherence to technology, starting with the selection of raw materials and ending with aging.

There is no need to rush in this process, since the quality of the future product, for which it is planned to use cereals, will depend on this.

If the whole process is presented step by step, it looks like this:

- Selecting a cereal crop, checking germination;

- Seed cleaning;

- Soak;

- Germination;

- Drying;

- Removing sprouts;

- Aging.

Each stage has some characteristics; they can be used for almost all cereals; only the aging periods can change. For example, if we consider rye malt, then 5-6 days will be enough to obtain sprouts, and 7-8 for wheat. There are also special signs of malt readiness, which will be described in detail below.

Selection of grains for malt

In order to make good malt, you need to choose the right raw materials. To do this, you need to pay attention to germination, which can be checked at home, as well as when the crop was harvested. As for maturity, it is better to give preference to last year’s harvest, in which case the seeds will be ready to show their germination in the shortest possible time. If the harvest is fresh, you will need to wait at least 2.5 months and only then start making malt.

Testing for germination will help eliminate unnecessary work, since in case low rate it is necessary to choose other raw materials.

To do this, take 100 seeds, throw them into the water, those that float up must be removed and the quantity added to a round number. The grains should be left in water or in a well-moistened cloth and left for 3 days. If no more than 10 of all seeds sprouted, then such raw materials are suitable and high-quality malt can be made from it. In case of low germination, you will have to purchase another cereal crop and it is better to make the purchase not in this store, since the product may be from the same batch.

Seed cleaning

Regardless of whether you plan to make rye malt, wheat malt, or any other malt, the seeds must be cleaned and disinfected to a certain extent. This entire process will not take much time, but will ensure the cleanliness and quality of the entire event. The purification stage may include the following stages:

- Filling all raw materials with warm water, approximately 30-40 °C, and then draining the liquid along with raised impurities, debris and empty seeds;

- Filling the grain container cold water(10-16 °C) and leave for an hour or 1.5, and then drain the water along with the garbage;

- Disinfection. A solution is prepared from pure water and iodine, amounting to 10 liters and 30-40 drops. Iodine can be replaced with potassium permanganate in a proportion of 2-3 grams or the amount on the tip of a knife for the same volume of water. Any of these solutions can be used to carry out a kind of disinfection of malt, leaving the seeds for 1.5-3 hours;

These measures will help to significantly reduce the likelihood of mold and mildew. This step is desirable, but not mandatory.

Soaking future malt

The stage is more preparatory, as it allows, at home, to saturate the grain with oxygen and moisture to a certain extent. The process takes about a day and consists of sequential changes of water. To begin with, the grains are poured with clean, but not boiled, water at a temperature of no more than 15 ° C, the whole mixture is carefully mixed and after 5-6 hours the liquid is drained, the mixture is left without water for 3-4 hours, stirred and poured again. Such manipulations can be carried out for up to 1.5 days, and the readiness of the seeds for germination can be determined by the increase in total volume, as well as by hardness. The seed no longer breaks, but becomes crushed and can be pierced with a needle.

Malt germination

At this stage, it is important to create optimal conditions for natural reactions to take place, and this is easy to do with your own hands. You should prepare a sheet or any other container in which you can evenly arrange the cereals in a layer of 1-6 cm; it is better to choose the middle one, since if the thickness is large, the lower layers will not have enough oxygen. It is important to ensure a uniform temperature regime, approximately 12-16 degrees. You will need a cotton cloth to cover the “small garden”; it will, if necessary, give moisture to the grains or, conversely, if there is excess liquid, partially absorb it. At least once a day it is necessary to change the water, carefully rinse the grain, and, if possible, ventilate the room,

The preparation time for malt may differ for each crop. If we consider a rye product, then its characteristic germination period varies from 4 to 5 days, for wheat it will take at least 6 days, barley ripens in 9-10 days. Rely only on the specified time interval, when you should not prepare malt yourself or at home; it is additionally recommended to check the condition of the grains. There are certain signs of malt maturity:

- The seeds are easily crushed and emit a special fresh smell, some compare it to a fresh cucumber;

- The length of the sprout for each type of malt may vary slightly. For example, if rye malt is grown, then the sprout should not be longer than the seed itself, but for barley the norm is a root that is 1.5 times larger than the grain;

- Sweetish taste. To determine it, it is enough to simply try the raw material, especially since it is very rich in many compounds during this period.

It is very important not to overcook the grain, as the nutrients will begin to be used for other purposes, and the purpose of this process is the processing of starch into sugar and subsequent fermentation.

Drying malt

At home, it is quite easy to properly dry sprouted grains. Carefully pour out the remaining liquid and place the mixture in the oven. The temperature to start is set at 40 degrees. Sometimes it is difficult to maintain such an interval, and the process itself can last more than a day, and an alternative could be a battery and laying out the grain in the sun. Malt dried in this way is already suitable for making moonshine. With a change in temperature, the color and, to some extent, the purpose of cereals will change. For example, if you increase the temperature to 80 °C and extend drying to 4 hours, then such a product is perfect for making dark beer. Drying is sometimes called a kind of fermentation and when it is carried out, a special sweetish aroma is released.

Removing sprouts

Since the sprouts will no longer be needed in the future, you need to get rid of them. This can be done mechanically. At home, this can be an ordinary bag into which processed grains are placed and shaken vigorously. Then you can bring a fan and blow through this entire mixture; naturally, this should not be done indoors.

aging

You should not immediately use malt to make moonshine or any other drink; it must be aged. Usually 30-40 days are enough for this, and only then can it be ground or used entirely for the production of various alcoholic beverages, conditionally without alcoholic drinks(kvass), dough and so on. It is important that the mixture is stored in a dry place and in a container or container that prevents the entry of pests and insects. It is believed that high-quality malt produces the most delicious and aromatic alcohol.

Experiments with malt production may sometimes not be advisable, since it is not always possible to achieve the desired result with your own hands. All activities can take at least a week and you need to constantly monitor the process, otherwise the grain may turn sour, dry out or overgrow. Such thorough observation is not suitable for everyone, so an alternative option is to purchase a ready-made, proven product. Its cost is quite reasonable, and manufacturers offer various varieties and types. You can separately choose rye, barley, made from other cereals, and also differ in fermentation. The choice is so varied that you can choose best option for the future production of this or that product will not be difficult.

Malt is a very healthy product: B vitamins and more, fatty acids, phytohormones, trace elements, minerals, folic acid, amino acids, enzymes. ...Of course, sprouted grain cannot be any different. True, preparing it is not an easy process: it is easier to buy ready-made barley malt. But those who prefer home-made alcohol and home-baked goods are not afraid of difficulties. How to prepare malt is worth talking about separately.

What is barley malt and how do you drink and eat it?

Malt is the result of germination of seeds. It is used to make beer, wine and whiskey, as well as bread. By the way, malt can be made not only from barley or rye, but also from oats, wheat and even corn. However, these types of malt are not beer malts and are only suitable for making wine and whiskey.

This product is needed because when maize, barley or rye sprouts, chemical changes occur in it, leading to diastasis. The latter is needed to dissolve and saccharify starch, as well as to produce maltose, a fermentable sugar. So, malt is a fermented product. In order to obtain malt for beer, the grain is first soaked and only then germinated. Changes begin to occur already during soaking, when the grain swells: diastase and carbonic acid are formed here. During germination, these processes become even more intense. This dissolves starch and produces glucose, sugar and maltose. It is moisture that starts all life processes in rye and barley.

Previously, it was believed that barley malt was only suitable for beer if no leaf appeared on it during germination. In fact, the leaf is needed, but it is only germinated at low temperatures. This must be taken into account before making malt at home. Only barley malt is used in beer production. Rye is most often used for baking or added to sweets, soups, main dishes, side dishes, and salads. It is also used in folk medicine, for example, for skin diseases and “female” diseases (for example, erosion). Malt is also used to treat hair: as a mask. But the main use of malt is to produce beer and other drinks. It is because of this, by the way, that beer is called liquid bread.

Barley malt can be dry or green.

How to make malt yourself: theory

First of all, you need to be prepared for the fact that this is a labor-intensive task.

The most important thing is to stop the growth of seeds in time so that they do not use up all their nutrients. To do this, barley malt (and any other) is dried.

When preparing malt for beer, it is important to choose the right grain. It must have a high ability to germinate. For newly harvested barley, it is small - it is better to choose grains harvested a couple of months (or more) ago. In addition, it’s good if all the barley is the same size: it’s easier to work with.

Malt for beer must be prepared with high-quality water. It should not contain heavy metals and chlorine. Best option– spring, filtered, from a well or settled.

Before you make malt at home, you need to check how intensively the grains sprout. Just soak a hundred or two grains, and after a couple of days see how many have sprouted. If 90 out of a hundred sprouts appear, this is normal germination. In other cases, it is better to use barley for other purposes.

Sprouting barley malt: practice

Malt cleaning

First, the malt for beer needs to be disinfected and cleared of debris that can interfere with germination.

To do this, take a bucket or large pan, and fill the cereals with warm water. Water (from 35 degrees to forty) should cover the grains by 5-6 centimeters. Stir after five minutes, remove debris and floating grains. Now pour cold water. We wait another hour. We remove the garbage again and drain the water again. Fill with new water, add iodine or potassium permanganate dissolved in water. For ten liters of water you need a couple of grams of potassium permanganate or three dozen drops of iodine. Drain the water after three hours. Sometimes it happens that after disinfection, barley may not germinate, but on the other hand, if it is not disinfected, mold may appear on the grain, that is, pathogenic microorganisms that destroy malt. So it’s better to decide for yourself whether to disinfect or not.

Fluid and oxygen saturation

The next thing to do with the barley is to soak it, saturating it with liquid and oxygen. It takes one and a half days, that is, 36 hours. All this time, you need to either fill the barley with water for 6 hours, or leave it dry. The water should cover the barley by three centimeters, its temperature should be about 12 degrees. After six hours, drain it along with the garbage, mix the barley and let it breathe for six hours and add water again. So all day and a half. This procedure should take place in the basement or any place where there is coolness and no light.

Malt germination

We germinate. One of the main moments of turning barley into barley malt. Here we start the process of breaking down starch and converting it into sugar. Here we will need a baking sheet or tray. Sprinkle the barley evenly onto it (the thickness of the layer is from a couple of centimeters to five). Cover the barley with a cloth (cotton) on top. It will absorb moisture that the grains do not need and release it if the grains need the liquid. The ideal room temperature would be 12-15 degrees. Also, the room should be well ventilated. Stir the barley every 24 hours and sprinkle it with water. It will germinate for about a week, but if the roots have appeared and are tangled so much that they can be unraveled, you can finish germination earlier. Rye germinates in about five days and on the last day it should not be watered. The roots of barley grains should be twice as long as the grain itself, while those of rye grains should be no longer than the grain itself. If the cereal has sprouted, it smells like cucumber and has a sweetish taste. Now we have green malt. This type of malt is used to make whiskey or moonshine, but green malt is stored for a maximum of three days. That is why we immediately move on to drying it.

Removing malt from water

To begin with, remove the remaining water from the tray with sprouted barley. Then it is transferred to a room or any other room where the air temperature is high. In winter, an area of the room near the radiator or stove is ideal for this. In summer, the attic and even the roof will do (if the weather is hot and no rain is expected). The drying process lasts four days. If roots have appeared, but there are still no sprouts, it can still be dried.

There is another option for drying malt: sprouted barley or rye is placed in the oven (temperature about 40 degrees) and dried for 30 hours. It is important to stir the grain every three hours.

Almost finish

The malt for beer is almost ready. If you want light beer or whiskey, dry it in the oven (temperature 80 degrees) and raise the temperature for the first half hour. The initial temperature is 30 degrees, then it is raised every five minutes. If the beer is dark, it is almost roasted: temperature is 105 degrees, drying time is 4 hours.

Separating grains from sprouts

All that remains is to separate the grain from the sprouts and let it stand. To do this, either knead the product with your hands so that all the roots separate, or pack it in a bag and roll it. The malt is then winnowed using a fan or in the wind.

Malt aging

Now it is put into bags and before preparing beer or whiskey we keep it dry and warm for at least a month. From barley, the malt yield is up to 79 percent, from rye - a maximum of 78.

- To grind your malt, use a coffee grinder, meat grinder, or even a grain crusher.

- You can use vinegar or vodka as a disinfectant. The last grains are rinsed and washed in vinegar for a long time. A mouthwash will also work, but you will need to rinse the stye afterwards to remove the smell.

- Barley can also be sprouted in the refrigerator.

- The grain must be clean, that is, without husks.

- If some of the barley is overgrown and some is sour, you can remove the sour and continue to deal with the overgrown.

- Whenever possible, purchase the highest quality barley or rye: this determines how they will germinate and what the taste of your beer will be.

- Sometimes beer made with homemade malt turns out to be pale in color. To give your drink a golden color, you can mix two types of malt.

Of course, in industrial conditions, malt is prepared differently and using malthouses. But if you brew the malt at home, you can make the beer completely unique.

Video instructions

Barley malt at home: how to prepare malt for beer and more

5 (100%) voted 6First, let's define what malt is, malt is a sprouted grain of cereals, rye, barley, wheat, any grain that has the ability to convert the starch contained in the grain and other substances into a soluble state under the influence of enzymes that are already in the sprouted grain, which is called green malt.

In dry grain, all life processes are minimized to allow the grain to survive the winter and germinate in the spring, in order to activate the processes inside the grain

It is necessary to moisten it and place it in conditions ideal for germination. Why do you need to moisten the grain and start germinating?

When grain is malted, fermentation processes occur in it, which determine its taste, color and color of malt.

This way you can make your own malt. Malt for mash or beer, make malt from barley, make rye malt for making homemade delicious drinks.

The technology for producing malt is largely the same.

Soaking of grain is carried out in an enamel container of sufficiently large volume. Soaking different types Soaking grain lasts for different times, for example, soaking rye for 25-30 hours, and barley for 50-60 hours.

We remove the floating (empty) grain.

During the soaking process, the water must be changed every 10-12 hours; in between, it is advisable to let the malt sit in the air for an hour, because oxygen is necessary to activate life processes in the grain.

After the soaking process has come to an end, it is necessary to disinfect the grain; for this we will need a weak solution of potassium permanganate.

Simply pour the resulting malt with potassium permanganate solution, mix and pour the potassium permanganate back, the disinfection process is completed.

After all germination and disinfection processes are completed, the malt must be placed for germination in some plastic jar or enamel container of small diameter so that the height of this container does not exceed 5 centimeters.

The duration of germination at room temperature of about 20 degrees will be different for different grains, so rye will germinate in about 3-4 days, and barley 6-8 days, all this time it is necessary to sprinkle the grain with water and stir about two to three times a day.

After the appearance of the Roots, the grain must be germinated further until the length of the Roots in rye reaches 1/3 of the length of the grain, and in barley it is approximately 2 times longer.

Fresh sprouted green malt can be stored for about two to three days, after which it will begin to mold and spoil. The taste of fresh malt is sweet, the grain crunches and has a pleasant aroma.

After preparing the malts, they can be stored for use; to do this, the malt must be dried at a temperature of no more than 50 degrees, poured into a canvas bag and stored.

This malt can be stored for quite a long time; in all recipes, the weight of malt is given based on the dry content.

How to make malt at home video!

Long before our era, the peoples of Mesopotamia discovered the secrets of converting natural saccharides into alcoholic beverages. Even then, people learned, by sprouting grains and boiling them, to obtain sugar from the starch contained in grains, from which they subsequently made drinks reminiscent of beer, which is familiar to us.

It turns out that making malt is one of the oldest chemical processes under human control. How can you get various types this product for making baked goods, different types of alcohol, etc.?

1 What is malt?

Malt is produced using three sequential processes: germination, drying and grinding of grain. After this, the ground product is boiled and the malt is turned into wort - malt broth.

To produce such a product, barley is most often used, but other grains can also be used: wheat, oats, rye, chumise and other crops.

The whole secret is that during the germination process, a special enzyme is formed in the grains - diastase, which breaks down the starch contained in the grain into simple sugars. Thus, saccharification of the raw material occurs. It is the sugars obtained in this way that, when interacting with yeast, are converted into alcohol.

You cannot mix different grains to make malt, since the germination and growth time of each crop is different.

This product is widely used in the modern food industry for baking bread, making alcoholic beverages, brewing, etc. In the beer industry, it is preferable to use barley malt, less often wheat malt. Rye and oats can be used to prepare alcoholic beverages other than oats and wheat. Bakers and confectioners prefer wheat and rye.

An important parameter for the quality of raw materials is the extractivity of the malt - the amount of active components that enter the wort during cooking. Extractive malt is valued much higher because it allows for improved fermentation processes and a higher quality final product than malt with low extractivity. For example, brewing malt must have a high percentage of extract, otherwise the fermentation process may not proceed at all.

1.1 The benefits of malt for the human body

It is also worth noting that malt is needed not only for the production of certain products. It is very valuable and useful product by myself.

Thanks to the large number of nutritional properties, vitamins and enzymes that this product has, its benefits are undeniable. It, both in its pure form and in the form of wort, is actively used in folk medicine as a general tonic and healing agent. It is rich in: calcium, phosphorus, selenium, manganese, magnesium, vitamin E and other vitamin groups. In addition, it contains a large amount of protein containing the entire set of necessary amino acids.

Different types of malt have different effects on the human body:

- Barley. Widely used for both prevention and treatment of diseases gastrointestinal tract. The reason for this is high content insoluble fiber, which improves the functioning of all digestive system, as well as helping to cleanse the body of waste and toxins. Vitamins B2, B3, E and A have a wound-healing effect on the mucous membrane, and vitamin B4 counteracts the formation of gallstones;

- Rye and oatmeal. These types of malt are the strongest immunomodulators. They are used for anemia, nervous and physical exhaustion, as a general strengthening and restorative agent. The use of this product in the postoperative period, as well as for people with diabetes, is very useful.

Attention! The use of malt for exacerbation of diseases such as: acute pancreatitis, gastritis with high acidity, cholecystitis, stomach ulcers and duodenum strictly contraindicated!

1.2 Malt preparation

The preparation of malt, both in production and at home, consists of several stages:

White malt is obtained using the method described above. It has the highest enzyme activity - at 80%. Other types of raw materials are prepared using the same algorithm. Depending on the desired end result, the process may include roasting, souring, or other processes.

1.3 How to make light and dark caramel malt in a slow cooker? (video)

2 Types of malt

Malt and wort are used to make bread and alcoholic beverages, including whiskey and various types of beer. It is clear that it is impossible to obtain different products from the same raw materials. To obtain different end products, different types of malt will be required.

In fact, there are many types of this product. We will look at just a few of them to understand the difference between them.

2.1 Fermented and unfermented

2.2 Sour

In addition to dark and light, there is also sour malt. The process of its preparation has nothing to do with fermentation, so it is worth talking about it separately.

To obtain sour raw materials, light dry malt, before brewing, is soaked in water at a temperature of 40-50 degrees and kept until 1% of lactic acid bacteria is formed. Then the raw materials are dried at a temperature of 50 degrees.